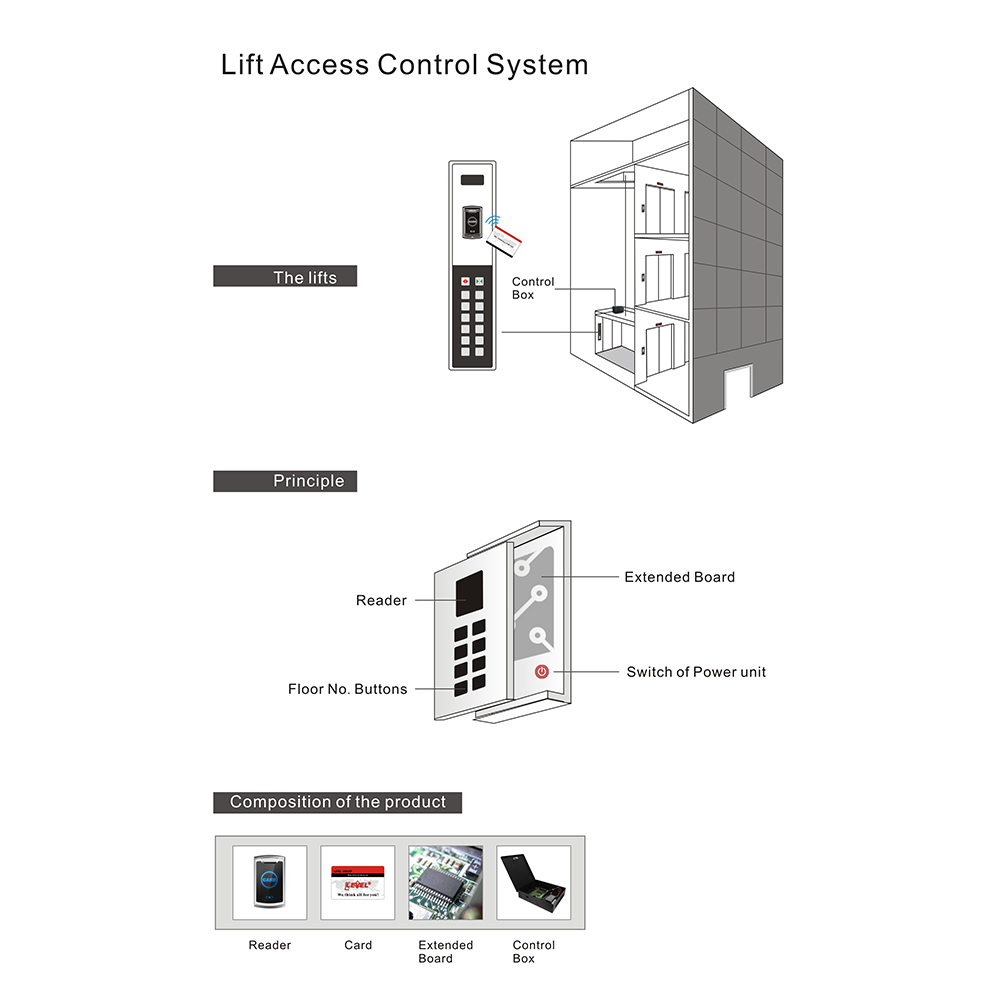

Connect by passive dry contact, LEVEL lift control system runs separately from the lift, safe and reliable.

Card right of calling lift can be programmed for one single lift or several different lifts, one certain floor or different floors, and with valid period.

Each floor of the lift can be set as “controllable” or “incontrollable”, and with valid period.

Blacklist management: 1000pcs cards can be put into the blacklist to avoid illegal use.